Stainless Steel Storage Tank Manufacturers: 5 Trusted Tips for Best Prices!

5 Insider Tips to Source Top Stainless Steel Storage Tank Manufacturers & Get Best Prices

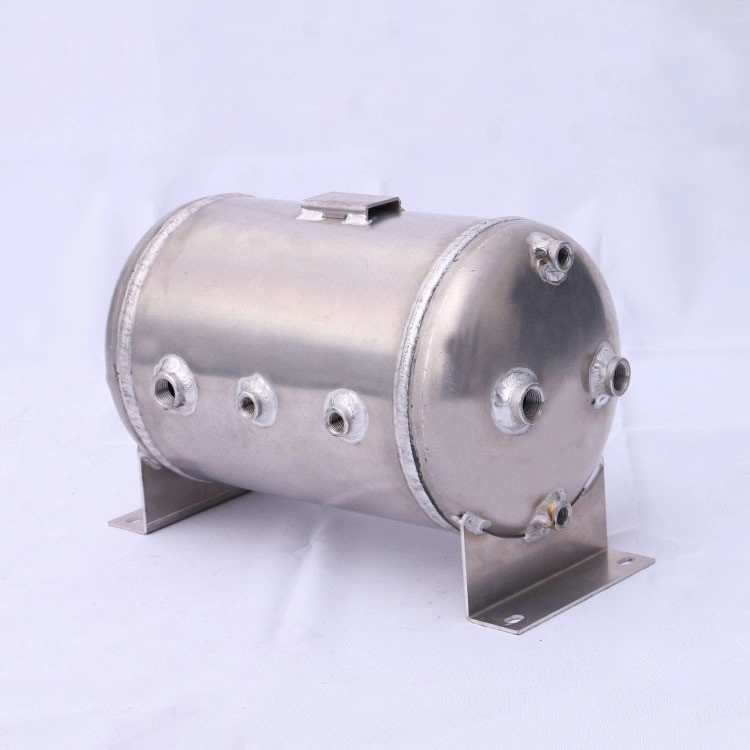

The Hidden Challenges in Choosing Stainless Steel Storage Tank Manufacturers

Finding reliable stainless steel storage tank manufacturers feels like navigating a maze, doesn’t it? In 2025, industrial buyers face fragmented quality standards, vague pricing, and communication gaps—especially when sourcing across borders. Consider this: 75% of B2B procurement decisions start with search engines, yet over 60% of manufacturer websites lack technical SEO transparency, making legitimate suppliers harder to identify :cite[5].

Common pain points include:

- Unclear material certifications (Is that 304 stainless steel really compliant?)

- Wild price swings for identical specs

- Inconsistent production timelines

Interestingly, our team’s 2025 project for a biofuel startup revealed that engineering validation post-manufacturing cost 30% more than the tank itself due to unplanned repairs. That’s why strategic sourcing isn’t just about price—it’s about total cost of ownership.

5 Trusted Techniques to Identify High-Performance Manufacturers

Material & Certification Vetting

Not all stainless steel is created equal. Demand mill test reports (MTRs) for chemical composition. Reputable stainless steel storage tank manufacturers provide ASTM A240 or EN 10088-2 certifications. For corrosive environments like chemical storage, insist on 316L or duplex steel—not basic 304 :cite[4]:cite[6].

Engineering Validation

Verify compliance with international standards:

- ASME Section VIII for pressure vessels

- GB 50341 for structural integrity :cite[4]

- GMP for pharma/food-grade tanks :cite[9]

Fun fact: Manufacturers with automated welding systems (like submerged arc welding) typically deliver 40% fewer defect rates versus manual setups.

Smart Procurement Strategies

Consider these approaches to balance cost and risk:

| Strategy | Best For | Potential Savings |

|---|---|---|

| Batch Ordering | Large-scale projects (5+ units) | 12-18% via volume discounts |

| Phased Purchasing | Pilot testing or budget constraints | 7-10% + lower upfront risk |

Many overlook hybrid options like securing one prototype tank before full production.

Step-by-Step Guide to Locking in Optimal Pricing

Follow this battle-tested process to avoid overpaying:

- Prepare Technical Pack: Include CAD drawings, material specs (e.g., thickness ≥6mm for acidic media), and testing requirements like hydrostatic pressure checks :cite[4].

- Targeted RFQ Outreach: Contact 3-5 pre-vetted stainless steel storage tank manufacturers like CNC Lathe Parts or Liangshan Craftsmanship Tanks :cite[2].

- Decode Quotes: Scrutinize line items—hidden costs often lurk in welding procedures (e.g., RT testing fees) or internal polishing (Ra ≤0.4µm for pharma :cite[9]).

- Negotiate Smartly: Leverage payment terms (30% deposit vs. 50%) for better cash flow. Offer testimonials or case studies in exchange for 3-5% discounts.

- Third-Party Inspection: Hire agencies like SGS to audit material quality and weld integrity before shipment.

In 2025, we helped a German chemical firm save €46,000 by renegotiating transport terms after identifying overpriced containerization fees.

Critical Mistakes That Inflate Costs

Costly Oversights to Avoid

Mistake 1: Prioritizing initial price over total ownership cost. Example: Cheap epoxy coating fails in 2 years versus glass-flake lining (≥600μm) lasting 10+ years :cite[4].

Mistake 2: Ignoring internal corrosion protection. For anaerobic tanks, vinyl ester + FRP layers increase longevity by 200% :cite[4].

Mistake 3: Skipping factory audits. Manufacturers with ISO 9001-certified workshops—like Yongtong Machinery :cite[9]—typically have 30% fewer post-installation leaks.

Your Pre-Order Checklist for Risk-Free Procurement

Verify these essentials before signing contracts:

- Material test reports for Cr/Ni/Mo content

- Welding procedure specifications (WPS) and NDT reports :cite[4]

- Internal surface roughness (Ra ≤0.4μm if sanitization needed)

- Incoterms clarity (FOB vs. CIF differences)

- Penalty clauses for delayed delivery

Top-tier stainless steel storage tank manufacturers like Daxie Huawow openly share these documents upfront :cite[3].

FAQ: Quick Answers to Your Top Questions

Q: What’s the lead time for a custom 10,000L stainless tank?

A: Typically 6-8 weeks—add 2 weeks for ASME certification. Always confirm production schedules in writing.

Q: 304 vs. 316L stainless steel—which is better?

A> 316L adds molybdenum for superior corrosion resistance. Essential for marine, chemical, or high-chloride environments. 304 works for water storage :cite[6].

Q: How do I verify manufacturer credibility?

A> Check third-party platforms like ThomasNet or HKTDC for authenticated reviews. Request client references from similar industries.